-40%

ALPHASENSE 3D CASTABLE RESIN FOR DENTAL AND JEWELRY APPLICATIONS(500ML)

$ 26.4

- Description

- Size Guide

Description

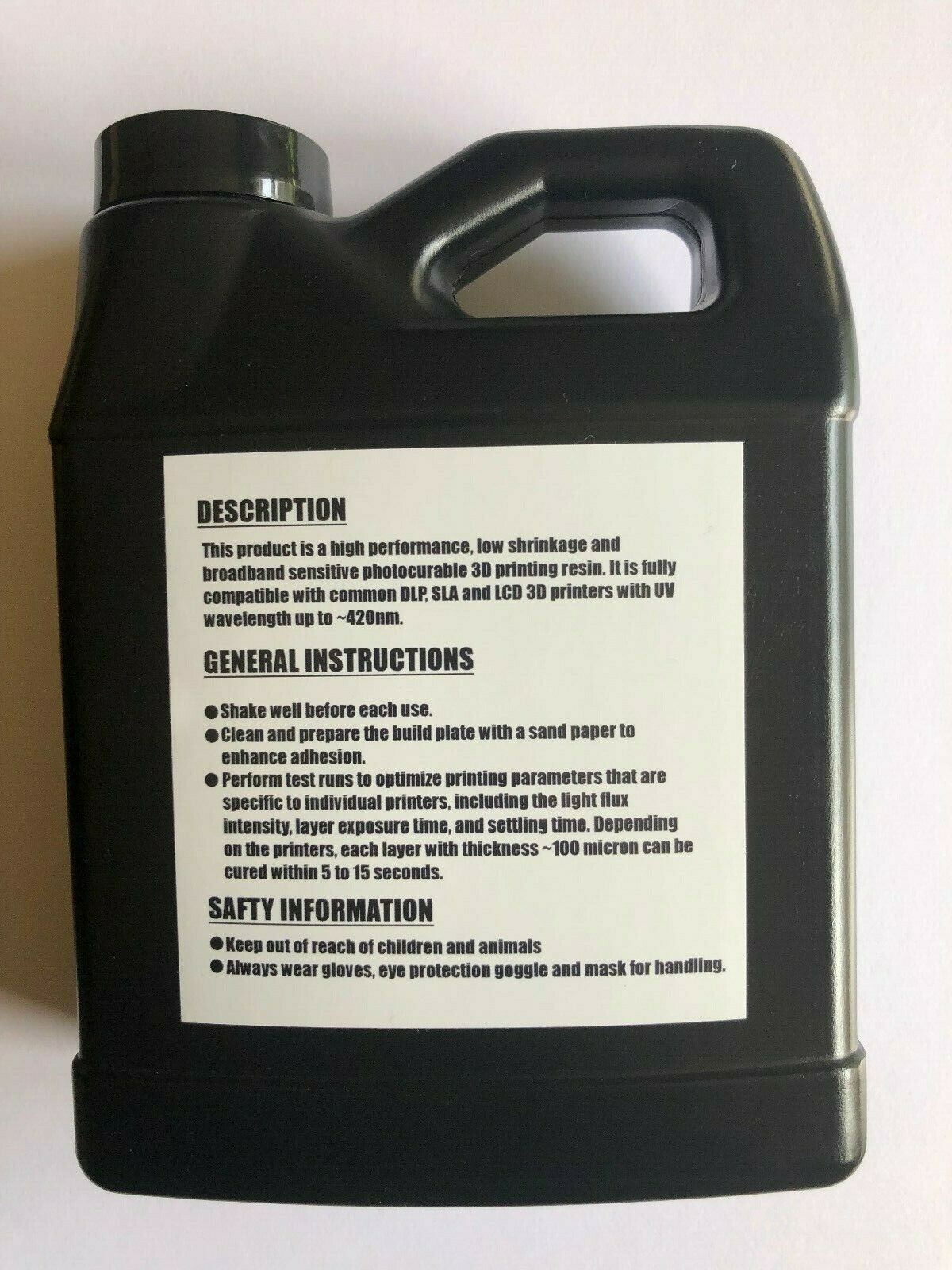

CAUTION: Recently many unauthorized sellers are listing counterfeited AlphaSense resin products on Ebay and other platforms. AlphaSense is the sole manufacturer and vendor of our resin products, and there is no authorized reseller within USA. Buyers need to be cautious about those fraudulent activities!What you are purchasing is the standard AlphaSense castable resin, which has been well received by numerous dental technicians and jewelry makers. With this resin product, you will enjoy the following benefits:

Fast curing and compatibility with a wide array of printers

. No matter what type of printer you are using (i.e. DLP, SLA and LCD), a model can be fabricated with a very high speed of ~1-2 inches/hour. For users with a DLP printer, each layer of ~100 micrometer thickness can be cured within 5 to 15 seconds depending on the light flux and model cross section. Users with LCD printers may need to use longer exposure time (e.g. 18 to 36 seconds/layer). The resin has a relatively low viscosity, thus allowing one to use a shorter (1-2 seconds) of resin immersion and settling time;

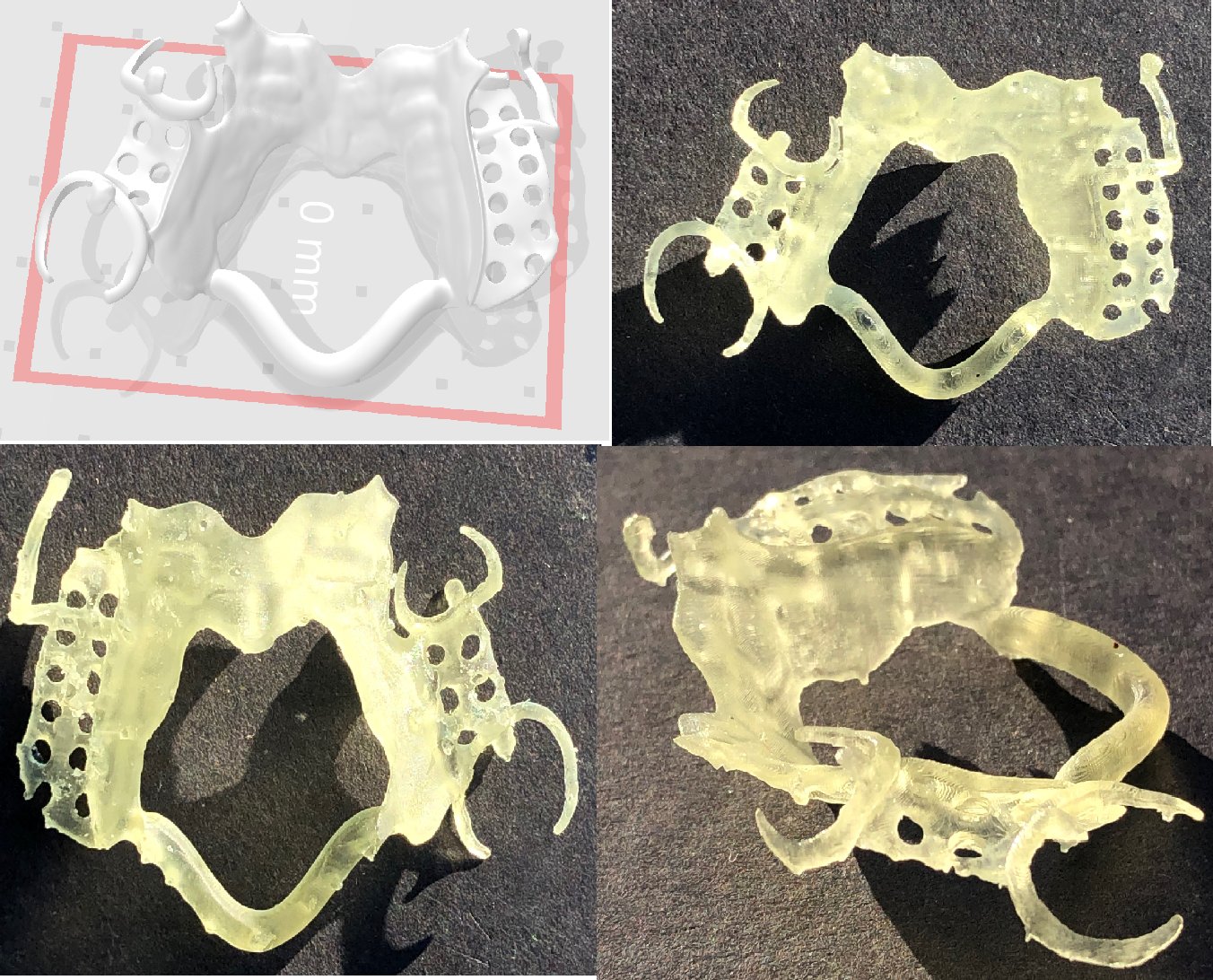

Smooth surface finish and high resolution

. Prints resulted from this resin product show very smooth surfaces. It is generally difficult to visually differentiate layer boundaries even if a relatively rough (i.e. 0.1 mm/ 100 micron) step size/resolution was used.

It should be noted that all the sample models were printed using a layer resolution of 100 micron for the capability demonstration. The resin allows resolutions in the range from 25 to 200 microns

;

Good Adhesion to the build plate

. The resin has a strong adhesion to the build plate. For users with LCD and SLA printers, this resin is ideal to ensure good plate coverage and adhesion.

After all, you don't want to see your model dropped to the vat bottom after hours of printing!

Easy cleaning and post curing. The resin can be cleaned with just warm tap water if you do not have isopropyl alcohol! Post curing can be easily visualized by color changes of the printed models.

Low odor and low volatile organic compounds (VOCs)

. Our unique material selection makes the resin have very low odor, which is drastically different from the resins supplied by some other vendors;

Our resin products have been successfully tested and their performances validated by hundreds of customers. The casting processes are very similar to the "lost-wax casting method" that the dental technicians and jewelry makers are used to. A standard polymer burnout schedule will be shipped with the product. Printing parameters for common printers will be provided as well. Negligible ash/resin residue will be left (i.e. <0.2%) after the polymer removal process, thus leaving a shape- and configuration-complementary cavity in the mold for subsequent casting to obtain high- quality dental parts and jewelry products, such as removable partial dentures, crowns, rings, necklace pendants, and bracelets etc.

Depending on the models, very little to no post- processing of the casting parts is needed!

Based on a recent survey of our existing customers, it appeared that our dental users prefer this standard resin over our wax product due to the better plate adhesion and faster curing speed. Please select accordingly based on your intended applications.

Each batch of resins was fully tested before it was shipped to our customers to ensure the best printing quality at a highly competitive price!

Note: Overseas customers may have to pay the import tax to the custom of your country.